Flexible cables

We provide a comprehensive range of flexible and highly flexible cables, catering specifically to applications demanding frequent movement. Whether it's for robotic operations or cable chains, our cable solutions are tailored to meet your needs.

Our flexible cables are primarily engineered for fixed installations, where they excel in handling tight bends and vibrations. However, they also exhibit resilience in scenarios involving intermittent motion and specific types of fixed installations. No matter which industrial application you have, our cables deliver the vital combination of flexibility and durability.

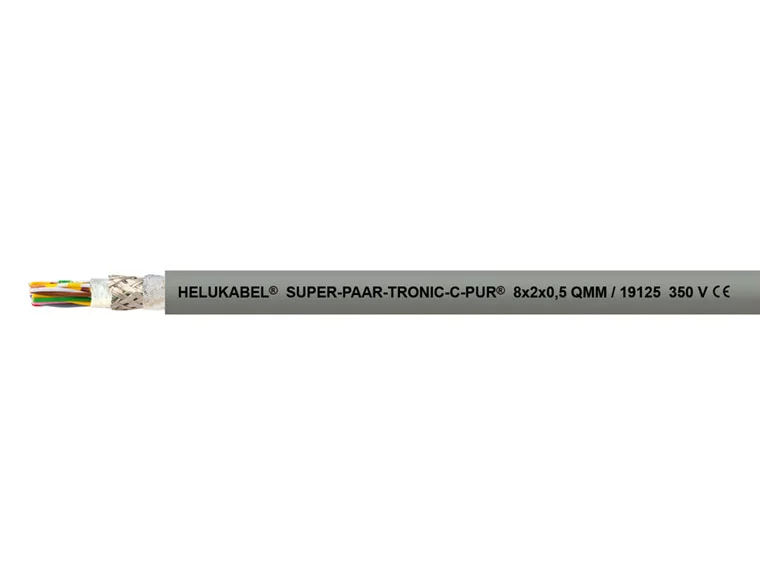

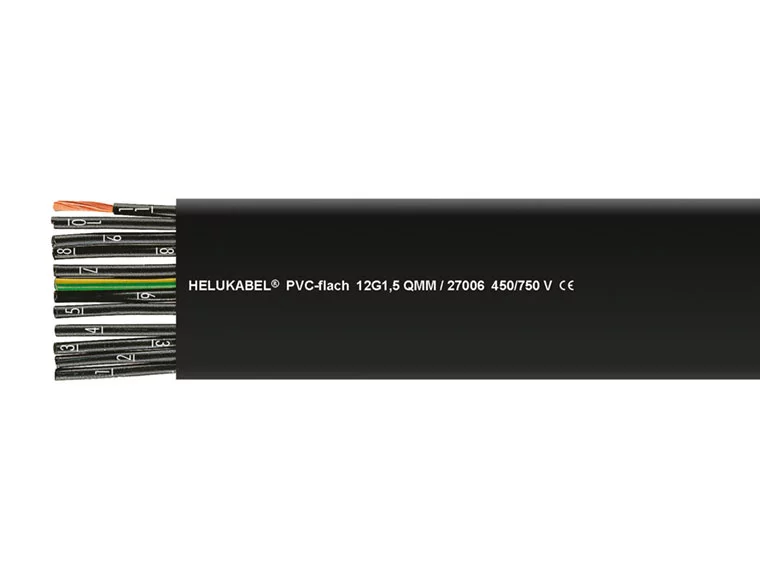

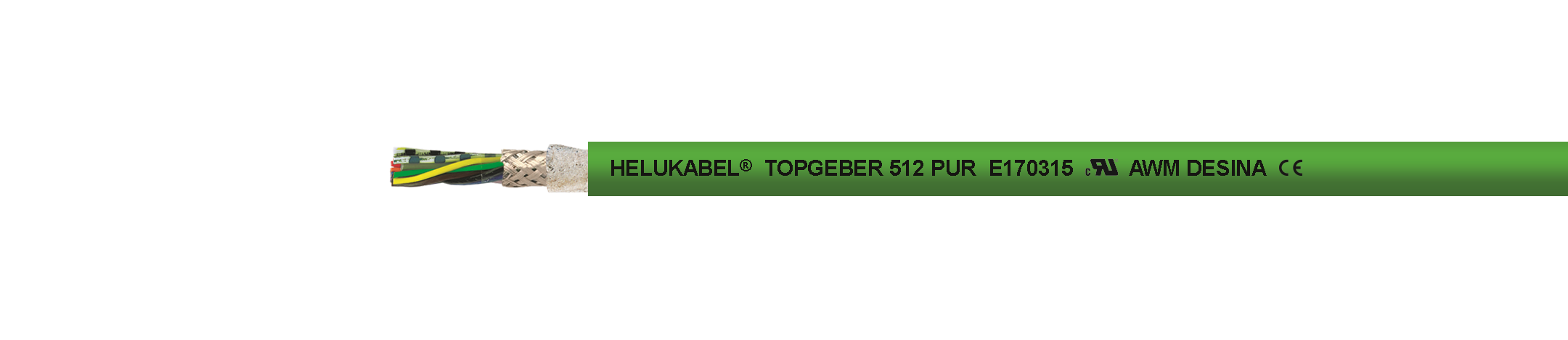

Our product range is extensive, offering various cable types such as control cables and motor cables, fabricated from materials like PVC, PUR, and TPE, ensuring suitability for cable chain usage, and these options are also available with shielding for enhanced protection. Furthermore, you have the flexibility to purchase our cables in full lengths or tailored to your specific length requirements. At HELUKABEL, you'll discover the perfect cable solution to guarantee seamless and dependable operations.

What is the difference between regular, flexible, and highly flexible cable?

| Regular | Flexible | Higly flexible | |

| Construction | Solid core with tightly bound copper or aluminum conductors. It has simpler insulation. | Multiple thin copper wires that are braided or spiral-twisted to increase flexibility. | A greater number of thin copper wires that are meticulously braided or spiral-twisted. |

| Flexibility | Limited movement and not designed to handle frequent bending or movement. | More flexible and capable of handling some degree of movement and bending. It is used in applications where there is some level of machine motion. | Extremely flexible and designed to withstand intense and complex movement, torsion, and bending. |

| Material | Insulation material such as PVC (polyvinyl chloride) to protect the conductors. | Insulation material such as TPE (thermoplastic elastomer) or PUR (polyurethane) to provide extra flexibility and durability against wear. | Insulation materials like TPE (thermoplastic elastomer) or PUR (polyurethane) to provide additional flexibility and abrasion resistance. |

| Use | Applications where moving is not a factor. | Moving applications such as conveyor belts or mobile industrial applications. | Robotics, CNC machines, and medical equipment where extremely precise and dynamic movements are required. |

How to choose the right cable for an energy chain?

Selecting the right cable amidst the myriad of designations, standards, and qualities can indeed be a daunting task. A guiding principle is that cables of higher quality often exhibit greater resilience to temperature fluctuations, accommodate longer travel distances, and demonstrate enhanced resistance to the impact of oils and chemicals. However, it's important to note that attaining optimal performance for your machinery or equipment doesn't invariably demand the utmost quality or the most expensive cable. Instead, your choice should hinge on the precise requisites of the application and the environmental factors it will confront.

With our extensive experience and comprehensive expertise in industrial automation catering to diverse demands, we are adept at assisting you in pinpointing the precise cable for your distinct application. Here are key facets to consider when selecting the ideal cable for your mobile application:

|

|

By thoughtfully addressing these factors, you can select the cable that perfectly aligns with your application, ensuring unwavering and effective functionality within the specific conditions it will operate in.

Data, coaxial and computer cables

Control and connection cables

Industrial ethernet and bus cables

Single cores

Motor, servo and feedback cables

Spiral and pre-assembled cables

Contact us!

| E-mail: info@helukabel.se | HELUKABEL AB |

| Spjutvägen 1 | |

| Phone: +46 8 55 77 42 80 | 175 61 Järfälla |